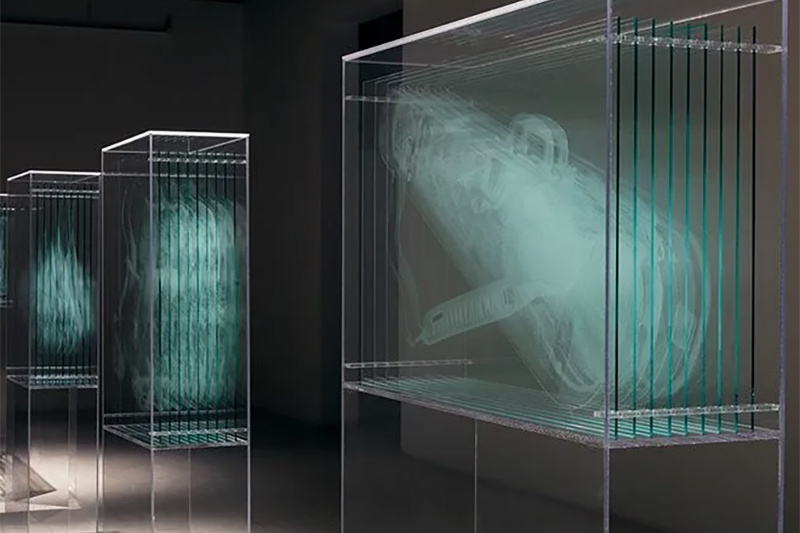

Electric heating glass is two or more pieces of tempered glass bonded together with PVB or specialized film, with a heating element sandwiched between the film and the glass. When powered on, the heating element generates heat, raising the temperature of the glass and achieving the function of the product. Electric heating glass is mainly used in the cockpit of various locomotives and ships, the portholes of ships, car windshields, and special requirements.

Product Features:

· Frost melting function: After being powered on, the surface temperature of the glass increases (usually 35-40 ℃) and remains above the dew point of the air, preventing frost and condensation from forming on the glass surface.

· Excellent optical performance: Using conductive wires and conductive films as heating media, the glass ensures excellent transparency and anti distortion performance, allowing drivers to observe objects clearly, realistically, and with high resolution through the glass.

· UV radiation protection function: Glass has high UV absorption capacity, which can effectively block UV rays from entering the room and reduce the damage of UV rays to drivers and indoor facilities.

· Safety: The structure of glass is a composite of organic and inorganic materials, which can maintain its integrity even after breakage and prevent breakdown. It has excellent safety.

Keywords

Electric heating glass

Electric heating glass

Contact Us

Product Catalog

ENTERPRISE ADVANTAGES

Committed to creating a safe and energy-saving new type of glass

Equipped with internationally advanced glass production lines, adopting strict quality control systems, focusing on continuous optimization and improvement of production processes, achieving intelligent and digital production processes, ensuring the stability and superiority of product quality.

Glass deep processing production line

We are highly confident of completing the project for you and offering our most thorough service.

Annual processing

We operate multiple production lines and are capable of producing in accordance with all your needs.

Exporting countries and regions

With rich experience in major projects, we guarantee punctual delivery as scheduled.

CUSTOMIZED

One Stop Solution

Our factory mainly produces: Special glass series products including bulletproof glass, anti smashing glass, anti-theft glass, fireproof glass, tempered glass, Low-E insulated glass, laminated glass, heated glass, nano energy-saving glass, intelligent dimming glass, sunshade glass, and screen printed glass.

Advanced equipment, modern management, high-quality raw materials.

We rely on our professional R&D team and engineers to create innovative solutions for the needs of our business partners

We have many years of export experience and our products are sold to over 30 countries.

PRODUCTION EQUIPMENT

Hollow glass

Hollow glass

Corporate equipment

Semi-automatic suction cup

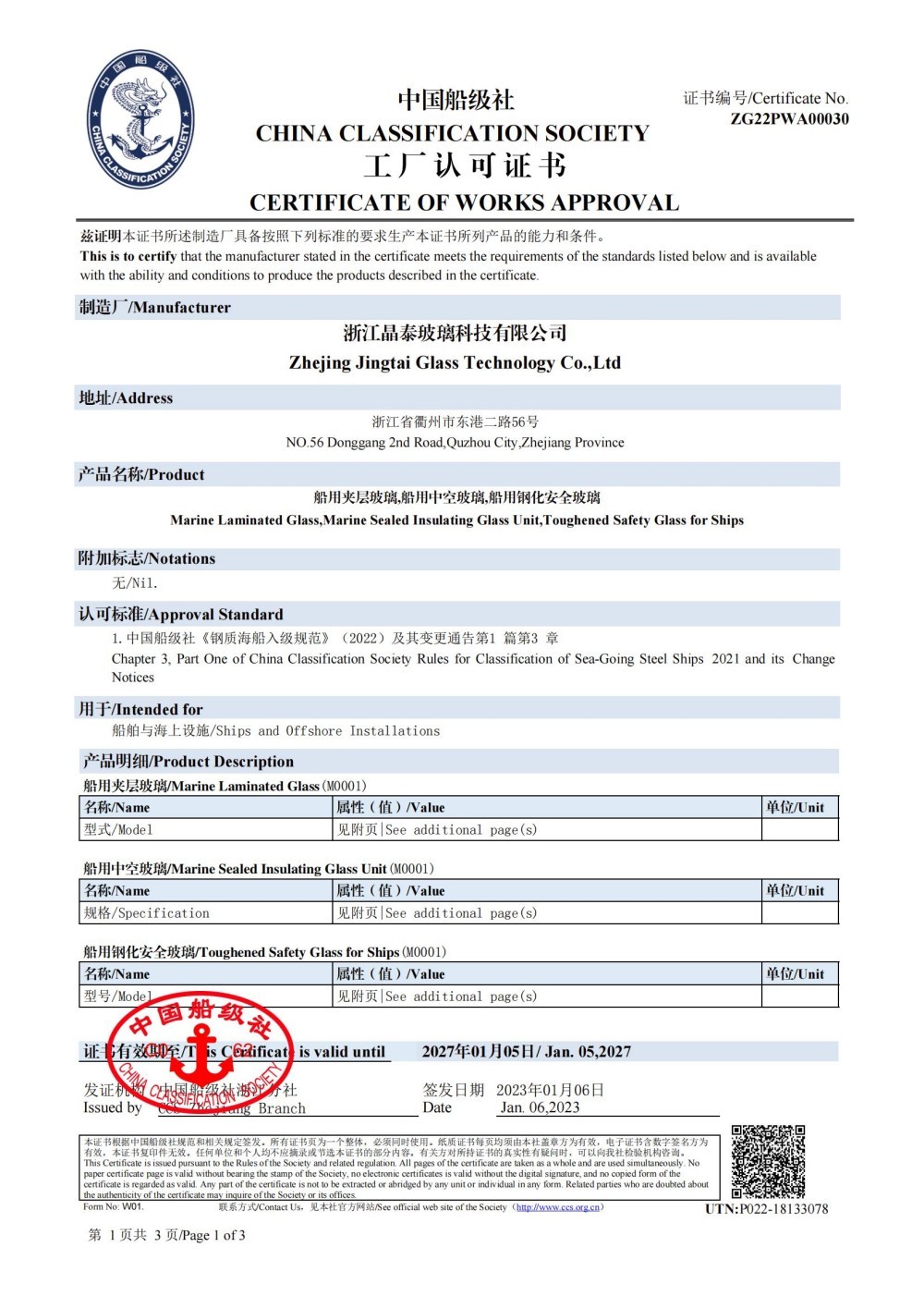

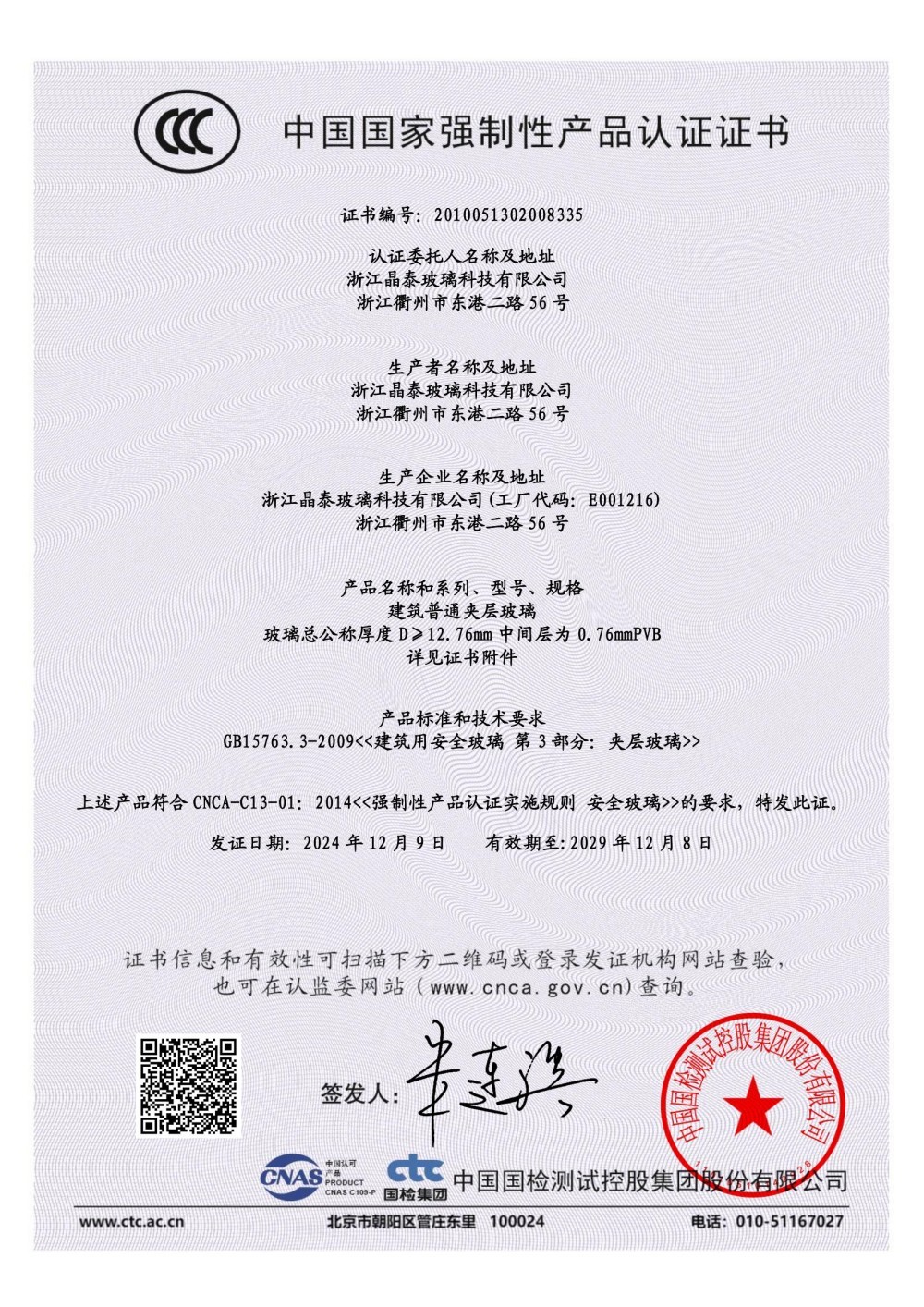

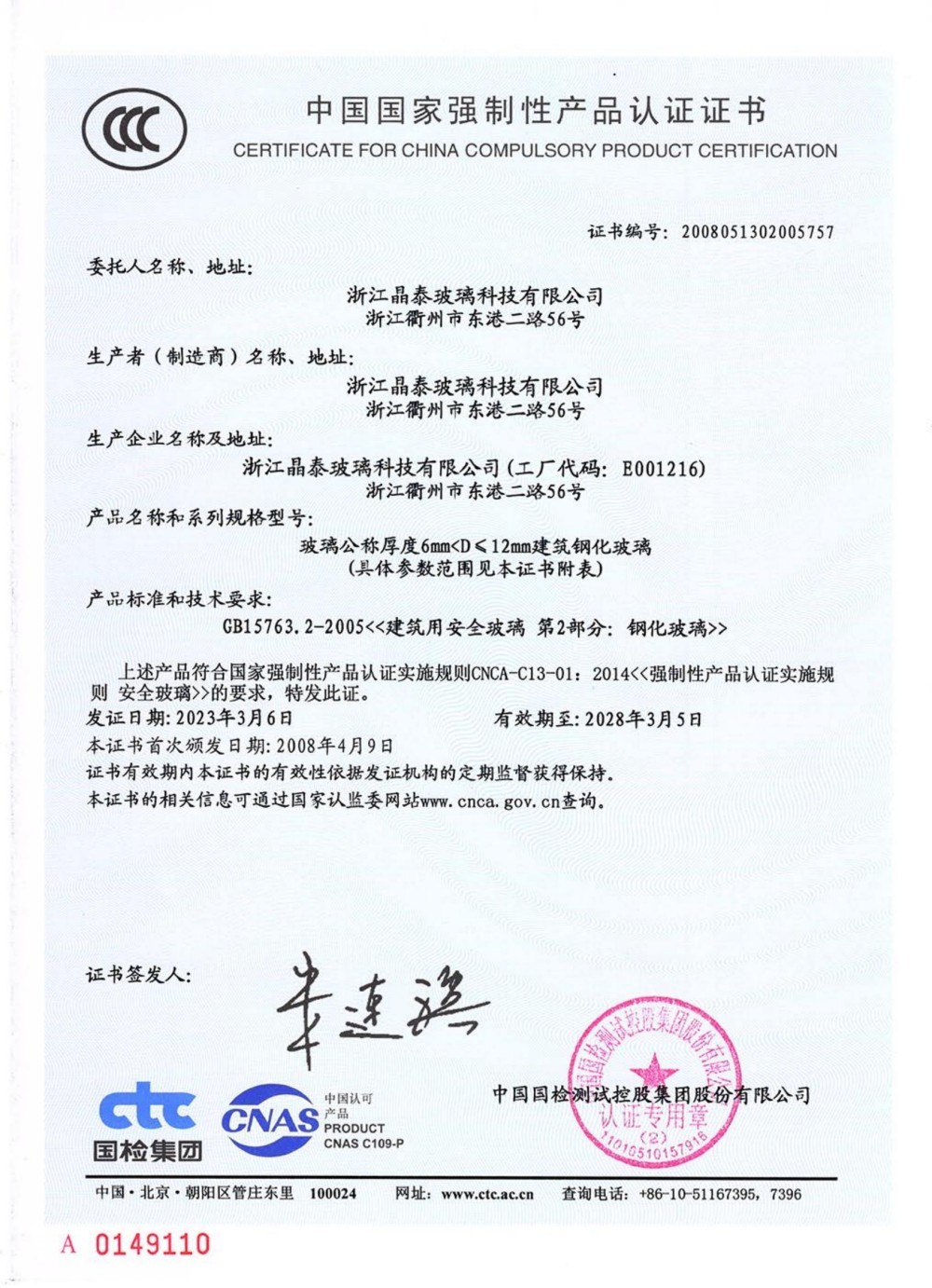

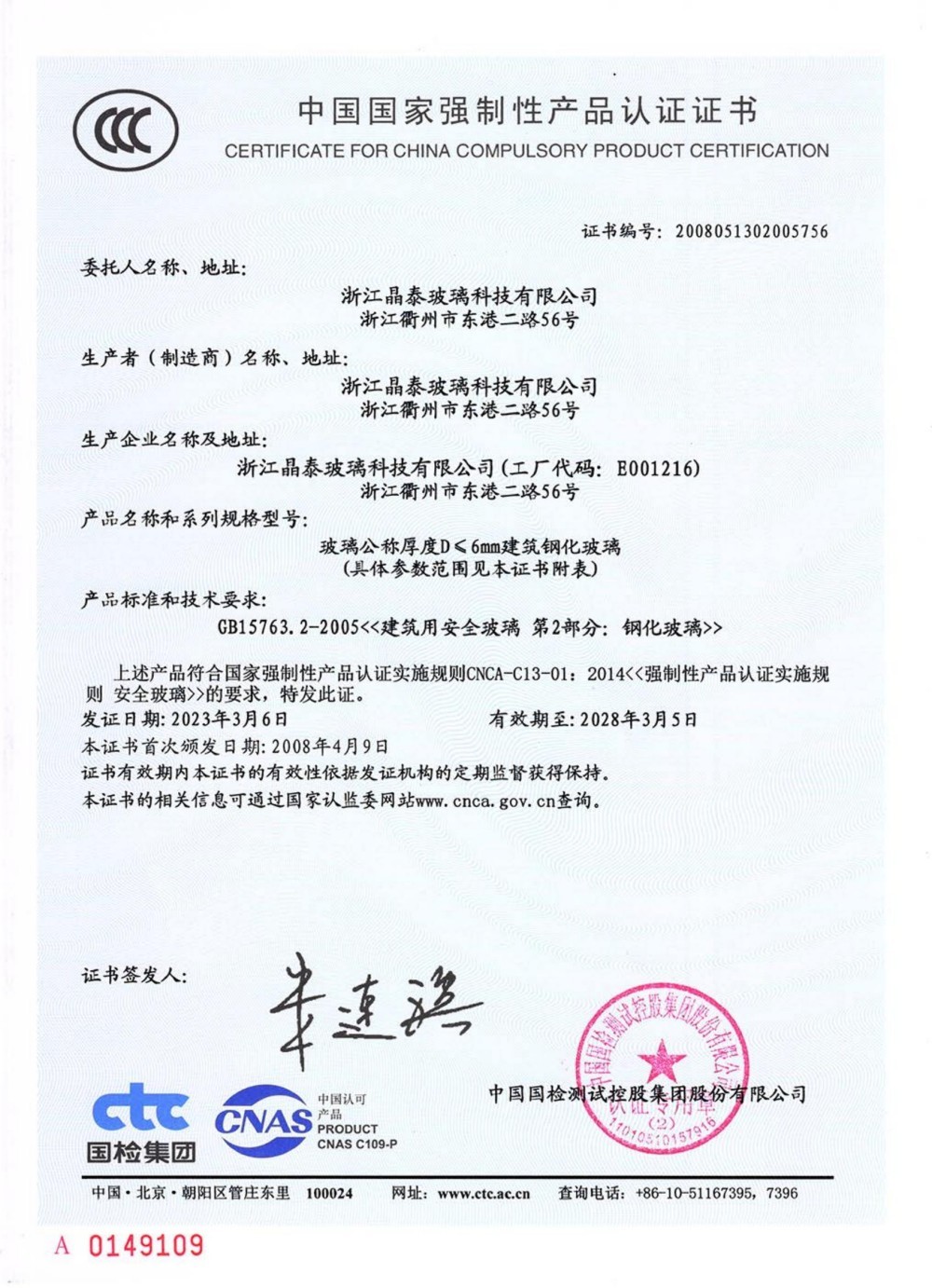

AUTHORITATIVE CERTIFICATION

OEM / ODM

CUSTOMIZATION PROCESS

Customer consultation and demand matching

Customer provided information: The customer contacts the factory through phone, email, online customer service, and other means to explain their general needs.

Proposal quotation and contract signing

Engineers conduct reviews based on customer requirements to confirm technical feasibility. For complex processes, it may be necessary to communicate multiple times with customers to optimize the solution.

Final payment: After the customer confirms that the order is correct, the remaining final payment shall be made according to the contract agreement.

Production processing and quality inspection

The factory purchases glass raw sheets of specified brand and thickness according to the order requirements. Use a CNC cutting machine for precise cutting.

Packaging Logistics and Delivery Acceptance

According to the product characteristics and transportation distance, different packaging methods are used (such as wooden boxes, iron frames, cardboard boxes with corner protectors, bubble wrap, etc.) to ensure transportation safety.

Establish multi-channel receiving entrances: set up dedicated after-sales service phone numbers, email addresses, and WeChat to ensure that customer issues are received in a timely manner.